Another product of Oraman Gharb Company is well casing pipes. With its long history in producing various types of pipes and fittings, it has been able to offer these types of pipes to its customers with the best quality and at a very reasonable price.

The use of UPVC pipes in well linings first occurred in Germany in the early 20th century. The characteristics of the raw materials used in the production of PVC well lining pipes led to their acceptance in well linings, one of the most important features of which was the longer life of well lining pipes compared to other pipes.

Many features have led to UPVC (polyvinyl chloride) pipes replacing metal pipes in well casings. Features such as their resistance to groundwater and salt water, as well as their lack of reaction to acids and bases, are the main factors that make this type of pipe superior to metal well casing pipes.

Over time, reactions occur between the water and soil, resulting in various acids, salts, and gases that are the main cause of rusting of metal pipes.

Polycarbonate pipes are resistant to electrochemical reactions caused by salts, acids, and bases that cause corrosion in metals, and this has led to the pipes replacing metal pipes in well casings around the world because they have a longer lifespan and are also more economically viable.

Another important feature of UPVC well casing pipes is that they do not produce chemicals over time and do not make the well water unusable.

And many other factors that made the research and development unit of Oraman Gharb Company think about producing well casing pipes so that it can respond to its valued customers in this field as well and, through the experience of its engineers and up-to-date production machines, offer well casing pipes to its customers with the best quality and the best price.

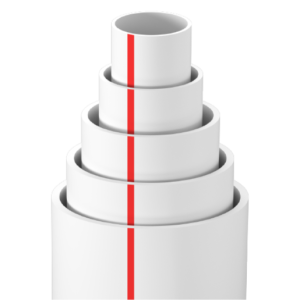

Given that the depth of the well, the internal diameter, and the method of gravel placement affect the external pressure of the pipe, pipes with different thicknesses, diameters, and grooves are used for different depths.

Well casing pipes of Oraman Gharb Company are produced in different sizes and thicknesses according to German standards, in mesh and plain (grooved and ungrooved) forms.

The thread type of this well casing pipe is as follows:

TR (trapezoidal) diameter 100 to 400 mm

R (Whitverse) diameter 80 to 100 mm

TRN (type without coupling protrusion)

You can see the technical specifications of Oraman Gharb Company well casing pipes in the table below.

| Standard | Size (inches) | Size | Thickness | The main unit | Sub unit | Weight per meter | Weight of each branch | Application |

| DIN 4925 | 10 | 280 | 12.5 | متر | 4متر | 16 | 64 | For use up to a depth of 150 |

| DIN 4925 | 10 | 280 | 16 | متر | 4متر | 20 | 80 | For use up to a depth of 300 |

| DIN 4925 | 12 | 330 | 14.5 | متر | 4متر | 21.75 | 87 | For use up to a depth of 150 |

| DIN 4925 | 12 | 330 | 19 | متر | 4متر | 28 | 112 | For use up to a depth of 300 |

| DIN 4925 | 12 | 330 | 19 | متر | 6متر | 28 | 168 | For use up to a depth of 300 |

| DIN 4925 | 14 | 400 | 17.5 | متر | 4متر | 31.75 | 127 | For use up to a depth of 150 |

| DIN 4925 | 14 | 400 | 21.5 | متر | 4متر | 38.5 | 154 | For use up to a depth of 300 |

| DIN 4925 | 16 | 450 | 19.5 | متر | 4متر | 40 | 160 | For use up to a depth of 150 |

| DIN 4925 | 16 | 450 | 23.5 | متر | 4متر | 47.5 | 190 | For use up to a depth of 300 |